Pex Pipe Installation Services for Property Owners

Visitors will learn about Pex pipe installation services and how to connect with local contractors who handle the work.

- - Pex pipe installation services for residential homes, including kitchens, bathrooms, and basements.

- - Commercial property projects requiring durable piping solutions for office buildings, retail spaces, and industrial facilities.

- - Contractors and local service providers specializing in precise, professional Pex pipe setup for new construction or renovation projects.

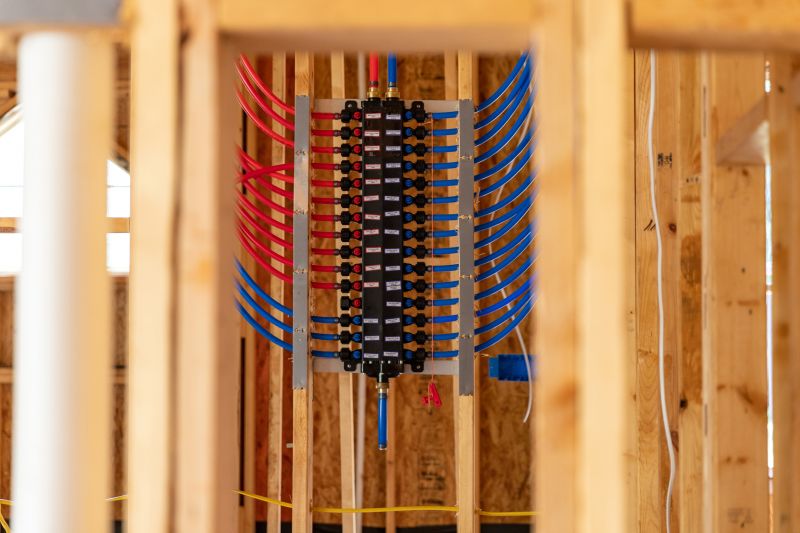

Pex pipe installation services involve the setup of cross-linked polyethylene piping systems, which are commonly used for plumbing, radiant heating, and other fluid transfer applications. Property owners often seek out local contractors who specialize in installing these durable pipes to ensure proper placement and secure connections. These professionals can handle a variety of projects, whether replacing outdated piping, expanding existing systems, or installing new infrastructure, providing the expertise needed for a reliable and long-lasting setup.

Local contractors offering Pex pipe installation typically work with homeowners, property managers, and business owners to assess project needs and recommend suitable solutions. They are experienced in managing different property types and can adapt to various installation requirements. Connecting with these service providers allows property owners to find qualified local pros who can deliver quality work tailored to their specific plumbing or heating system needs.

This guide provides helpful information to understand Pex pipe installation and what to consider before starting a project. It assists in comparing local contractors and service providers to find the right fit for your needs. The goal is to help you gather the basics to make informed decisions and connect with experienced local pros.